Open Type Single Crank High Precision Power Presses metal stamping punching press machine for automotive metal tensile stamping sheet metal parts.

Contact Us• In order to guarantee the machine running in stable and smooth, adopts the design of symmetrical two balancer.

• The precision of mold adjusting up to 0.1 mm, safety, reliable and convenient.

• Crank, gear, connect bar are oxidized hardening and milled having super comprehensive mechanical performance and durable function.

• Reasonable structural design, is convenient for automatic production and line production.

• Used reliable high intensity clutch/brake and twin electromagnetic valve, overloading protector can guarantee safe production all-around.

|

Standard Unit |

Optional Accessories |

|

Inverter |

Electrical automatic lubrication system |

|

Hydraulic over-load protector |

Pneumatic die cushion device |

|

Manual Slide adjusting device (model GTP1-60 and those below it) |

Foot switch |

|

Electric Slide adjusting device (model GTP1-80 and those above it) |

Quick die change device ( Die lifter, die clamper or die moving arm ) |

|

Manual die height indicator (model GTP1-60 and those below it) |

Knock-out device for the upper side of Slide |

|

Electric die height indicator (model GTP1-80 and those above it) |

Missfeed detection consent |

|

Balancing device for Slide and mold |

Shakeproof mechanical foot |

|

Crank angle indicator |

Photo-electronic safety device |

|

Stroke counter |

Feeder |

|

Air source receptacle |

Uncoiler |

|

Against over-run safety device |

Leveler |

|

Air ejector |

Robot hand |

|

Power socket |

Die lighting |

|

Touch pad (Preset, total counter) |

|

|

Model

|

GTP1-25

|

GTP1-35

|

GTP1-45

|

GTP1-60

|

GTP1-80

|

||||||||||||||||

|

V

|

H

|

V

|

H

|

V

|

H

|

V

|

H

|

V

|

H

|

||||||||||||

| Capacity | Ton |

25

|

35

|

45

|

60

|

80

|

|||||||||||||||

| Rated Tonnage Point | mm |

3.2

|

1.6

|

3.2

|

1.6

|

3.2

|

1.6

|

4

|

2

|

4

|

2

|

||||||||||

| Variable Speed | s.p.m |

60-140

|

130-200

|

40-120

|

110-180

|

40-100

|

100-150

|

35-90

|

80-120

|

35-80

|

80-120

|

||||||||||

| Stroke Per Minute | s.p.m |

110

|

85

|

75

|

65

|

65

|

|||||||||||||||

| Stroke | mm |

60

|

30

|

70

|

40

|

80

|

50

|

120

|

60

|

150

|

70

|

||||||||||

| Max. Die Height | mm |

200

|

215

|

220

|

235

|

250

|

265

|

310

|

340

|

340

|

380

|

||||||||||

| Slide Adjustment | mm |

50

|

55

|

60

|

75

|

80

|

|||||||||||||||

| Slide Area | mm |

300×220×50

|

360×250×50

|

400×300×60

|

500×360×70

|

560×420×70

|

|||||||||||||||

| Bolster Area | mm |

680×300×70

|

800×400×70

|

850×440×80

|

900×500×80

|

1000×550×90

|

|||||||||||||||

| Shank Hole Diameter | mm |

Ø38.1

|

Ø38.1

|

Ø38.1

|

Ø50

|

Ø50

|

|||||||||||||||

| Main Motor | kw×p |

3.7×4

|

3.7×4

|

5.5×4

|

5.5×4

|

7.5×4

|

|||||||||||||||

| Slide Adjusting Device |

Manual operation

|

||||||||||||||||||||

| Air Pressure | kg/cm² |

6

|

|||||||||||||||||||

| Presses Precision |

JIS 1 Class

|

||||||||||||||||||||

| Presses Dimension | mm |

1390×920×2125

|

1450×990×2300

|

1650×1040×2390

|

1670×1090×2750

|

1820×1330×2980

|

|||||||||||||||

| Presses Weight | Ton |

2.1

|

3

|

3.8

|

5.6

|

6.5

|

|||||||||||||||

| Die Cushion Capacity | Ton |

-

|

2.3

|

3.6

|

3.6

|

3.6

|

|||||||||||||||

| Die Cushion Stroke | mm |

-

|

50

|

70

|

70

|

70

|

|||||||||||||||

| Die Cushion Effective Area | mm² |

-

|

300×230

|

350×300

|

350×300

|

450×310

|

|||||||||||||||

|

Model

|

GTP1-110

|

GTP1-160

|

GTP1-200

|

GTP1-260

|

GTP1-315

|

||||||||||||||||

|

V

|

H

|

V

|

H

|

V

|

H

|

V

|

H

|

V

|

H

|

||||||||||||

| Capacity | Ton |

110

|

160

|

200

|

260

|

315

|

|||||||||||||||

| Rated Tonnage Point | mm |

6

|

3

|

6

|

3

|

6

|

3

|

7

|

3.2

|

8

|

4

|

||||||||||

| Variable Speed | s.p.m |

30-60

|

60-90

|

20-50

|

40-70

|

20-50

|

50-70

|

20-40

|

40-50

|

20-40

|

40-50

|

||||||||||

| Stroke Per Minute | s.p.m |

50

|

35

|

35

|

30

|

30

|

|||||||||||||||

| Stroke | mm |

180

|

80

|

200

|

90

|

200

|

100

|

140

|

150

|

250

|

150

|

||||||||||

| Max. Die Height | mm |

360

|

410

|

460

|

510

|

460

|

510

|

500

|

550

|

500

|

550

|

||||||||||

| Slide Adjustment | mm |

80

|

100

|

110

|

120

|

120

|

|||||||||||||||

| Slide Area | mm |

650×470×80

|

700×550×90

|

850×630×90

|

950×700×100

|

1000×740×100

|

|||||||||||||||

| Bolster Area | mm |

1150×600×110

|

1250×800×140

|

1400×820×160

|

1500×840×180

|

1600×900×200

|

|||||||||||||||

| Shank Hole Diameter | mm |

Ø50

|

Ø65

|

Ø65

|

Ø65

|

Ø65

|

|||||||||||||||

| Main Motor | kw×p |

11×4

|

15×4

|

18×4

|

22×4

|

30×4

|

|||||||||||||||

| Slide Adjusting Device |

Manual operation

|

||||||||||||||||||||

| Air Pressure | kg/cm² |

6

|

|||||||||||||||||||

| Presses Precision |

JIS 1 Class

|

||||||||||||||||||||

| Presses Dimension | mm |

1970×1458×3140

|

2390×1560×3800

|

2690×1790×4100

|

2865×1950×4470

|

2965×2145×4500

|

|||||||||||||||

| Presses Weight | Ton |

9.6

|

16

|

23

|

32

|

36

|

|||||||||||||||

| Die Cushion Capacity | Ton |

6.3

|

10

|

14

|

14

|

14

|

|||||||||||||||

| Die Cushion Stroke | mm |

80

|

80

|

100

|

100

|

100

|

|||||||||||||||

| Die Cushion Effective Area | mm² |

500×350

|

650×420

|

710×480

|

810×480

|

810×480

|

|||||||||||||||

|

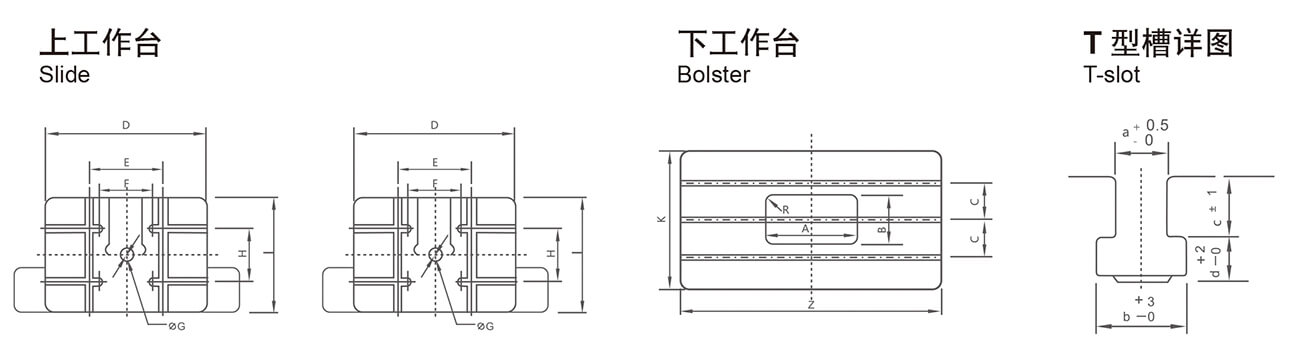

Model

|

A

|

B

|

C

|

D

|

E

|

F

|

G

|

H

|

L

|

T型槽

|

|||

|

a

|

b

|

c

|

d

|

||||||||||

| GTP1-25 |

240

|

120

|

90

|

300

|

|

150

|

Ø38.1

|

80

|

220

|

18

|

30

|

18

|

12

|

| GTP1-35 |

280

|

140

|

120

|

360

|

|

160

|

Ø38.1

|

100

|

250

|

18

|

30

|

18

|

12

|

| GTP1-45 |

300

|

150

|

120

|

400

|

|

210

|

Ø38.1

|

120

|

300

|

18

|

30

|

18

|

12

|

| GTP1-60 |

320

|

160

|

150

|

500

|

220

|

220

|

Ø50

|

160

|

360

|

22

|

37

|

24

|

16

|

| GTP1-80 |

360

|

180

|

150

|

560

|

300

|

220

|

Ø50

|

180

|

420

|

22

|

37

|

24

|

16

|

| GTP1-110 |

400

|

200

|

160

|

650

|

300

|

220

|

Ø50

|

220

|

470

|

22

|

37

|

24

|

16

|

| GTP1-160 |

440

|

220

|

220

|

700

|

300

|

175

|

Ø65

|

220

|

550

|

22

|

37

|

24

|

16

|

| GTP1-200 |

480

|

240

|

280

|

850

|

420

|

200

|

Ø65

|

300

|

630

|

22

|

37

|

24

|

16

|

| GTP1-260 |

520

|

260

|

290

|

950

|

420

|

200

|

Ø65

|

300

|

700

|

22

|

37

|

24

|

16

|

| GTP1-315 |

520

|

260

|

290

|

950

|

420

|

200

|

Ø65

|

300

|

700

|

22

|

37

|

24

|

16

|

The company is committed to fine management and zero defect operations. The company has implemented enterprise information management such as ERP, in order to provide customers with more timely, better quality and higher value-added products, and continue to promote the update and upgrade of the industry. Based on the business philosophy of "service-innovation-value", adhere to the quality policy of "pursuing excellent quality, starting from me". The products are widely used in various mass production metal processing, punching, shearing, forming, extension, such as auto parts, home appliances, electronics, hand tools, hardware, computers, mobile phones and other product processing. At the same time, it provides various supporting automation equipment, which is growing steadily. At the same time, the company's main products, punches, presses, precision punches, high-speed punches and pneumatic punches have a good reputation among customers. Customer satisfaction is our greatest value! Welcome customers and experts to visit and guide!

Vision and Value: with efficient team-work and seamless cooperation from every employee and supplier, make the most cost-effective metal stamping presses domestically in China.