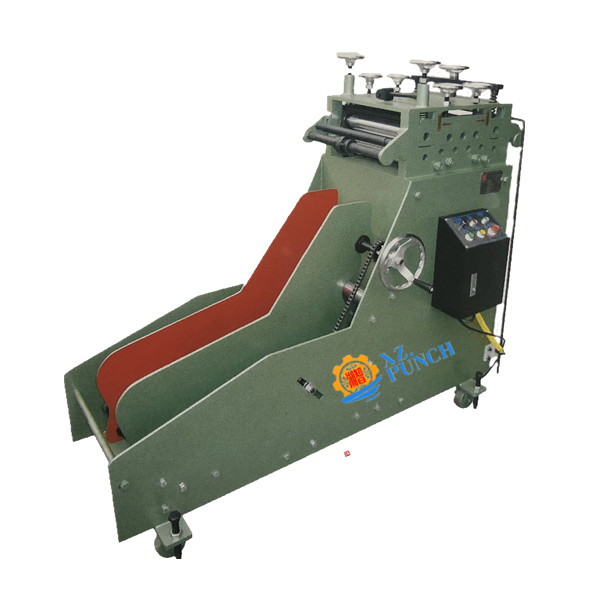

Features

• Precise micro-adjustment device, suitable for precision processing

• Use Japanese electromagnetic contact and electric parts, long service lite

• Integrated with Uncoiler and straightener, small volume, simplify feedingoperation, reduce cost

• All rolls are made of bearing steel, have all been quenched, hard-chromeplated and grinded with mim HRC60

• Equipped with Frequency converter and induction system

• Suitable for continouse press processing of various hardware, electricselectric appliance, toys and auto parts; precise and wearable

Special devices(selective) Change feeding speed

• Add material press device Change the interior diameter, or hydraulic uncoil

• expansion is for selection Material weight can be changed according to demands

• motor can use double-shift control or double-frequency converter device control

| type | CL-150 | CL-200 | CL-300 | CL-400 |

| Material width(mm) | 150 | 200 | 300 | 400 |

| Material thickness(mm) | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 | 0.5-3.0 |

| Speed of feed | 15m/min | 15m/min | 15m/min | 15m/min |

| Motor | 1HP | 1HP | 1HP | 1HP |

| Material O.D | 1000 | 1000 | 1000 | 1000 |

| Material weight | 400KGS | 500KGS | 500KGS | 500KGS |

| Machine weight | 350KGS | 400KGS | 450KGS | 500KGS |

| Machine L*W*H(m) | 1.6*0.6*1.4 | 1.6*0.7*1.4 | 1.7*0.8*1.4 | 1.8*0.9*1.5 |